VEZZADINI is an Italian company specializing in packaging equipment technology and packaging butter, animal butter , margarine, cheese and other dairy products.

VEZZADINI the brand is present in the international market for over 50 years, with a loyal customer base in over 30 countries in Africa especially in Europe and America. Today VEZZADINI can offer a complete solution for your needs butter packaging machines, animal butter, margarine, cheese and other dairy products, whether packaged in:

- Flexible Film (film, aluminum, paper etc …)

- Pots and plastic trays with

- corrugated boxes;

- Metal boxes.

It also provides packers (packers) end of the line to the cardboard of the products listed above.

VEZZADINI uses the most modern and reliable techniques to meet your expectations by ensuring speed after-sales and quality.

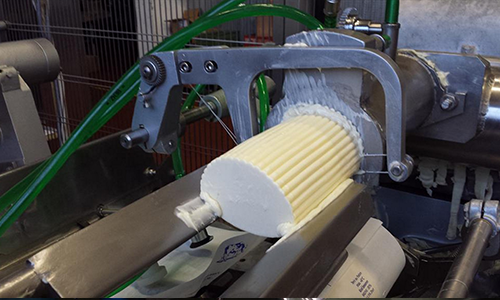

These machines are mainly mechanical, designed to work in a wet environment, equipped with high-precision metering, and robust construction low-maintenance

Their design is ergonomic, with great flexibility to change quickly and easily format.

Range of packaging machines

Intended for the packaging of butter, Vegetable butter, margarine, cheese and other dairy products in flexible film (paper, aluminum ... etc) for small capacity (07grs 25 grams), average capacity (50 grams to 1000 grams) and large capacity (1 kg to 10 kg).

According to different types of folding (folding portfolio, lateral bending, micro bread ...etc)

Range of fillers

Intended for the packaging of butter, Vegetable butter , margarine, cheese and other dairy products in:

- Pots and plastic trays with installation cover and seal heat sealing and for the small and medium capacity (10 grs to 5000grs).

- Plastic Cardboard boxes for large capacity (10 kg to 25 kg).

- Metal boxes with independent sealing machines for medium capacity (200 grams to 1000 grams).

Range of packers

Coming at the end of lines and which are intended for the automatic or semi-automatic setting cardboard into several layers and several rows of the abovementioned products (packages, trays, jars, cans etc…).